Shears

Guillotine Drive System - provides superior strength and durability compared to all other shear drive systems.

Quick-Change Blade Gap Adjustment - all models have either manual or power blade gap adjustment for fastest set-up.

Linear Blade Motion - straight line cutting action produces superior edge quality compared to swing beam/rocker arm shears.

Precision Ball-Screw Drive Back-Gauges - insures precision cutting from end to end with travel speeds up to 500 IPM,

Automatic Indexing - ensures back-gauge stays calibrated without requiring the operator to stop production to make adjustments.

Construction - compare our weights and warranty to all other competitors.

Capacities - available for materials from 10 ga to 1.5" and lengths up to 22'

Made in the U.S.A. - built from non-proprietary parts available in the USA. Proudly owned and operated 100% in the U.S.A.

Warranty - Our unmatched 5 Year Parts/2 Year CNC/5 Year Limited onsite labor comes standard with every machine

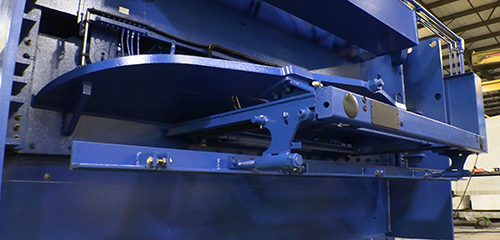

GUILLOTINE DRIVE: What separates U.S. Made machines from the imports?

100% American Guillotine drive system with straight line cutting action. Unlike most imported swingbeam/rocker arm shears that have top blades that pivot from the end frames and shear in an arc or “swing”, Standard Industrial utilizes a true guillotine drive system that shears straight down.

Straight line cutting means that the relationship of the top blade to the workpiece never changes throughout the cut providing the best cut possible. Our US made shears are rated to 80,000 tensile and 44,000 yield strength.

5 YEAR PARTS/2 YEAR PLC & 5 YEAR LIMITED ONSITE LABOR WARRANTY

The best warranty in the business. All hydraulic, mechanical and electrical components are covered by our 5 year parts warranty. The CNC control is covered for 2 years. If you have any issues, contact our service department, we troubleshoot the problem and send you the parts.

What separates us from the rest, is that if we cannot identify the problem over the phone, we send a technician to your facility to take care of the issue at no cost to you, for the entire 5 year warranty period in the contiguous U.S.

A LIFETIME SUPPLY OF OFF THE SHELF COMPONENTS

All Standard Industrial machines come with a lifetime supply of components. Beyond our 5 year parts warranty you will never have to worry about finding parts. We use nothing that is proprietary, our parts are available everywhere in the USA.

We supply you with a manual that lists all the components original manufacturer’s names and part numbers so you are not forced to come back to us for components.

SIMPLE, EFFECTIVE PLC SHEAR CONTROL

|

|

|

EXTREMELY HEAVY DUTY, BALLSCREW BACKGAUGEBallscrew precision with unyielding strength best describes our beast of a backgauge.

All 10 gauge to ½” capacity shears come equipped with a 36” travel, precision ballscrew backgauge (Backgauge pic here) (optional 48” travel available). All 5/8” up to 1.5” capacity shears come standard with 48” travel backgauges.

All shears have programmable X retract and manual swing-away (power swing-way available optionally). Precision lead screws, powerful motors and a massive frame covered by our 5 year parts warranty, provide a gauging system that will last decades. |

|

QUICK-CHANGE BLADE GAP ADJUSTMENT

All model AS shears come standard with a quick-change blade gap adjustment. The 10 gauge up to 3/8” capacity shears from 6’ to 12’ lengths come standard with a side adjustable, manual quick-change system (available optionally with a power blade gap system).

All ½” and larger and all 14’ and longer shears come standard with an Automatic quick-change blade gap system. This powered system allows the operator to input the desired material thickness and the CNC control automatically sets the machine to shear that capacity. If an optional rake adjustment is included, the rake is automatically set as well.

|

TABLE FEATURESAll shears come standard with hand slots and t-slots in the table. A t-slot across the front edge of the table for sliding optional support arms left to right is included. All ½” and larger and 14’ and longer shears come standard with heavy duty ball transfers in the table for easier part handling—optional on ¼” & 3/8” shears x 12’ and shorter. All shears some standard with our fully OSHA approved, heavy duty awareness barrier to protect operators during shearing process |

SQUARING ARM

All shears come standard with a 4’ squaring arm (measured from the blade) with an imbedded precision scale. Available optionally in 8’ or 12’ lengths.

ALL SHEARS ALSO INCLUDE

- Massive, welded frame with overbuilt tables to last generations

- Adjustable hold down pressure for sensitive materials

- Simple and efficient CNC control

- Shadow lights that provide a shearing line

- Footswitch control

- OSHA approved awareness safety barrier protecting the operator from shearing area

- Lifetime telephone support at no charge

- The most efficient and simple hydraulic system available making maintenance and troubleshooting easy.

MODEL AS SHEAR OPTIONS |

|---|

TABLE OPTIONS |

|---|

Squaring Arms:

All shears come standard with a 4’ squaring arm (4’ from blade--2’ off table). 8’ and 12’ arms can be added. Longer squaring arms also available. An additional squaring arm can be mounted on left side (high end of rake). Optional ball transfers can be mounted on squaring arms.

Support Arms:

24”, 36” or 48” t-slot support arms are available to slide left to right in the t-slot across the front edge of the shear table. These arms have machined t-slots on top for optional disappearing/gravity stops. They are also available with imbedded scales and imbedded scales can be machined in the table. Optional ball transfers can also be mounted to support arms.

Accessories for Support Arms and Squaring Arms:

Disappearing/gravity stops for t-slot arms, protractors for angle shearing and swing stops for squaring arms are available.

Table Machining Options:

All shears come standard with T-slots and Hand slots in the table as well a t-slot across the front edge. Additional hand and t-slots can be added optionally.

Ball Transfers:

All ½” and larger and all 14’ and longer shears come standard with heavy duty ball transfers in the table. All 10 gauge, ¼” and 3/8” shears from 6’ to 12’ can have ball transfers added.

BACKGAUGE OPTIONS |

|---|

Travel:

All 10 gauge up to ½” capacity shears come standard with 36” travel gauges and are available optionally with 48” of travel. All 5/8” and larger shears come standard with 48” of travel.

Power Swing-away:

All shears come standard with a simple, manual swing-away backstop when shearing material longer than the machine’s backgauge travel is required. A power swing-away option is available that automatically swings the backstop out of the way when needed. This option also gives you 48” of travel.

BLADE ADJUSTMENT OPTIONS |

|---|

Infinitely Variable Power Blade Gap Adjustment:

The operator can input the desired material to shear and the CNC control will automatically set the machine to shear that material. This automatic feature is standard on all ½” and larger and 14’ and longer shears.

Manual quick-change blade gap adjustment is standard on all 10 gauge, ¼” and 3/8” shears from 6’ to 12’. The automatic power blade gap adjustment can be added optionally.

Rake Adjustment:

All shears come standard with a low fixed rake. We offer a variable rake option that allows a lower rake setting for purposes of slitting and keeping the drops flatter if required.

HIGH PRODUCTION OPTIONS |

|---|

Automatic Lubrication System:

Using a grease reservoir on a timed system, this option allows you to set the rate and amount of lubrication as needed for your level of production. Warning light and automatic shut down when the reservoir is empty is included.

Pneumatic Sheet Support and Conveyor Systems:

This system supports thin material to allow it to make contact with backstop for gauging. The arms are pneumatically powered and move out of the way during shearing process. It includes sloped surface to allow material to slide out from under the backgauge for easier retrieval. These systems also available with conveyors and stackers.

CNC Front Gauging System:

CNC controlled front gauging system available with 2 to 3 (or more) drives and in 6’, 10’ or 12’ lengths. Available with ball transfers beams and air driven fingers.

High Speed Hydraulic Packages:

Faster strokes per minute systems available for all shears. These systems come with oil coolers. Oil coolers can also be included without high speed packages for higher temperature environments.

HOLD DOWN CYLINDER OPTIONS |

|---|

All shears come standard with extremely heavy duty hold down cylinders that provide the strongest holding force available. The hold down pressure on the cylinders is also adjustable for more sensitive material.

Cylinders with Impact Pads:

Each hold down cylinder is capped with Nylatron pads for mar-free applications.

Extra Hold Down Cylinders:

Add an extra hold down cylinder on left side of shear (high end of rake) for small piece work on both ends of shear.

Independent Hold Down Actuation:

Allows hold downs to actuate independently from blades to hold material in place before shearing.

EXTENDED WARRANTY |

|---|

On top of our unmatched standard 5 year parts/2 year CNC and 5 year limited onsite labor warranty we offer an optional additional 2 year parts warranty for a total of 7 years. No other manufacturer offers this warranty.

OTHER OPTIONS |

|---|

Onsite Training:

Due to the simplicity of our shear, onsite training is rarely needed and is not included as standard, however it is available optionally.

Paint Color:

We can paint your machine any single industrial enamel color. A paint sample is required.

Customization:

We welcome requests for tailor fitting your machine to your needs. Including process line shears, robotics, scrap shears and more. Contact us for your special requests.

SHEAR SAFETY |

|---|

|

Standard Awareness Barrier: All shears come standard with our OSHA approved physical awareness barrier to protect operators during the shearing process. Although fully compliant, this physical barrier allows the operator to get as close as possible and allows ample visibility into shearing area. |

|

|

Optional Light Curtains: Infra-red light curtain systems are available in lieu of, or in addition to, the standard physical awareness barrier that protects the operator from the shearing area. Light curtains allow full view and no physical obstruction to the shearing area while still protecting the operator. |

|

Optional Physical Barriers on Back of Shear:

Physical interlocking barriers/cages that protect the entire area behind the shear. When open, the machine is automatically turned off.

These barriers are also available with infra-red light curtains in lieu of interlocked doors.

|

Compliance Options:

UL, CSA and ZED compliance options are available. Other compliance options available upon request.

|

PNEUMATIC SHEET SUPPORT AND CONVEYOR SYSTEMS Pneumatically powered supports - keeps thin gauge material from drooping down in order to make contact with the backstop and prevents deformation during the cutting process. REQUIRES AIR SUPPLY (90 psi, xx C.F.M MINIMUM)

|

|

|

| Conveyor System - Conveyor systems include pneumatic sheet support and a belted conveyor to move the material from cutting area to the included, “trim cut” container. Conveyor systems can be combined with stackers to automate shearing operations. |  |

Stacking System - Mechanically aligns cut materials and stacks them in a holding bin up to the full length of the shear.

| CUSTOM SHEAR PRODUCTIVITY |

Proudly made in the U.S.A., Standard Industrial Company custom hydraulic sheers are some of the heaviest duty shears on the market today. They utilize a Guillotine drive system that keeps the angle of the cut consistent throughout the entire stroke length, providing the straightest, most distortion free results possible. Able to shear or straight line cut materials from 10 ga. to 1.5" thick, our machines boast the strongest hold down tonnage in the industry. Standard Industrial also offers a line of process line shears to coincide with your sheet metal feeding system. Whether this system is feeding via a roll or robotics, we can supply the shear for your line.

Available in sizes from 6' to 22' wide, we supply all systems with complete hydraulics, table, apron, and optional PLC controls. Manufactured from only the most durable materials, they operate at pressures to 3,000 psi, and are 100% O.S.H.A. and ANSI B11.4 compliant. Fully tested in-house and again after installation at your facility, we guarantee each piece of equipment is operating to your expectations. Built to last, a custom hydraulic shear from Standard Industrial will provide you with 30+ years of low maintenance, workhorse operation and become one of your most valuable capital assets.

Our confidence in the equipment we build is backed by an unmatched 5-year warranty. Contact us today to learn how we can help out with your equipment needs.

| ROBOTIC INTERFACE CAPABLE |

|

| CONVEYOR SYSTEMS |

|

| HIGH PRODUCTION PROCESS LINE SHEARS |

|

CUSTOMIZATION

EXPANDED METAL SHEARS

Just one example of customization is for the shearing of expanded metal. Special solid bar-type hold down systems with longer travel are a perfect solution for this industry.

|

Hold down bars in lieu of hold down cylinders make shearing larger size diamonds much easier.

|