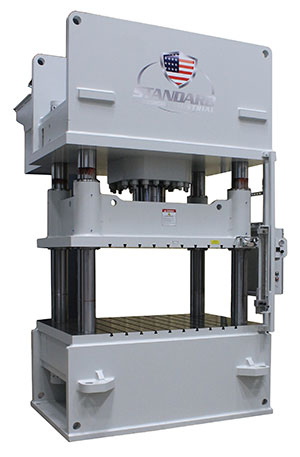

Model AP Four Column Presses

Applications - Specifically designed for long draw applications as well as large die requirements with center-load and/or even tonnage across the bed. From 100 to 1,500 tons.

Versatility - Accommodates a large variety of dies for trimming, deep drawing, stamping, die cutting / tryout and many other applications

Accessibility - 4-sided access makes loading and unloading dies/parts easy,

Precision - Superior rigidity and ram to platen parallelism

Customization - Custom bed sizes and stroke lengths available

Controls - Available from simple limit switch operation to full PLC control and/or Process Line integration

Compliance - All Standard Industrial machines are UL508A compliant. Other compliance levels available per special quote.

Made in the U.S.A. - built from non-proprietary parts available in the USA. Proudly owned and operated 100% in the U.S.A.

Warranty - Our unmatched 5 Year Parts/2 Year CNC/5 Year Limited onsite labor comes standard with every machine.

Model AP Four Column Press

Our 100% US manufactured model AP Four column press is one of the most versatile and reliable presses available today.

Our model AP presses are widely used in applications which need to accommodate a large variety of dies for applications such as trimming, die cutting/tryout, deep drawing, stamping and much more.

All model AP Four post presses are built with the quality standards you would expect from a machine made in the USA. Top to bottom parts and structure reliability ensure years of dependable operation. Backed by our unmatched 5 Year parts + 5 Year limited onsite labor warranty you are guaranteed a lifetime of proven performance.

- Simple and safe setup and operation

- Proportional and non-proportional systems available

- Simple limit switch ram control as standard with PLC options

- Center load and even tonnage across the bed are perfect applications for the model AP.

The model AP four column press is guided by heavy duty A660 bronze bearings (available everywhere in the USA) along turned, ground and polished chrome columns to ensure years of maintenance-free, reliable operation.

These high-speed production presses are designed with maximum contact to bearings for uniform control. Parallelism and flatness dimensions are critically held tolerances on all presses.

HYDRAULICS

The hydraulic cylinder(s) are manufactured with urethane lip type seals, bronze bearings and shafts of chromed 1045 steel, turned, ground and polished. The system is self-contained and complete with oil cooler. It also includes a filter, overload protection, a hydraulic pressure tonnage gauge and control and a counterbalance valve to absorb shock in punching operations. A pilot operated check valve is supplied to prevent drifting of the ram and a decompression system is also provided to reduce shock at the bottom of the travel.

Simple, easy to operate and maintain with parts availability everywhere in North America.

FEATURES

- Ideal for center load and even tonnage across the bed applications

- Self-contained hydraulic system with oil cooler and filter

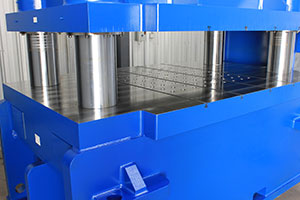

- T-slots in the bed and ram

- Two hand control station

- A counterbalance valve for punching and a decompression system for bottoming applications are standard equipment on all Standard Industrial presses

- Machine tool quality direct hydraulic cylinder

- Perfect for long stroke and drawing applications

- Adjustable shaft packing

- Tonnage control

- Completely adjustable open height, stroke and speed change point

- Extremely heavy duty welded frames

Applications

- Embossing

- Drawing

- Stamping

- Die Try-out

- Sizing

- Rubber Pad Forming

- Forming

- Swedging

- Trimming

- Punching (Due to the overall weight of the ram and the drive system, when punching or blanking with a four column press, you should limit your overall tonnage to 50% tonnage unless stroke dampers are used.)

- Blanking (Due to the overall weight of the ram and the drive system, when punching or blanking with a four column press, you should limit your overall tonnage to 50% tonnage unless stroke dampers are used.)

All Model Press Available Options |

CUSTOMIZATION

We welcome requests for customization of any of our machines. Many aspects of all machines can be contoured to match your requirements.

HYDRAULIC SYSTEMS

We offer conventional and proportional hydraulic systems engineered to your requirements.

START UP/TRAINING

Onsite training at the customer’s facility is available optionally. Due to the simplicity of the operation of our base model presses, onsite training is rarely needed. Onsite training is included with the purchase of the optional PLC ram control. Please note that all machines must be fully installed, rigged in place, leveled/bolted down, oil in reservoir and hooked up electrically prior to the arrival of the technician.

EXTENDED WARRANTY SERVICE

This package includes all the features of our standard warranty plus: A 7 year parts in lieu of standard 5 year parts warranty

T-SLOT CONFIGURATION

(NOTE) (2) 5/8” t-slots are standard on all presses in the bed and ram (running left to right) T-slots sizes are available in 5/8”, 3/4” or 1” T-slots in the bed and/or ram. Special T-slot sizes are available

LUBRICATION SYSTEMS:

Manifold Lubrication System

Brings all lubrication points to one area.

Automatic Lubrication System

Automatically lubricates machine with EP-1 grease. Includes warning light when oil is low & auto-shutoff

PNEUMATIC QUICK-CHANGE TOOLING SYSTEMAir actuated die lifters in press bed for easy and quick die change and quick set ups. |

|

SAFETY:

Hand/Foot Safety Sequence with Footswitch

Allows operator to use (2) hand pedestal control until “slow down” speed at which time the footswitch can used for remainder of stroke.

Light Curtain Safety Barrier

Infra-Red light curtain across front of press that stops operation of machine if light curtain is broken. Blanking with programmability included by request.

Interlocking Side barriers

Physical barriers for protecting operator that shut the machine down if removed. Can be alone or used in conjunction with light curtains

Additional Control Stations and/or Pedestals

NOTE: (1) Palm button station is included with all presses.

Palm buttons can be mounted to bed/ram or additional pedestals on floor for multiple operators

Gear Lock Safety Systems

Interlocking mechanical gear system that provides physical stops to prevent ram dropping.

OPERATIONAL PREFERENCES:

Pressure Reversal of Ram

Allows the ram to return to top of stroke once a pre-set pressure/tonnage is achieved.

Auto Cycle Remote

Allows ram to stoke automatically without operator actuation. NOTE: requires safety barrier or light curtain.

Dwell Under Tonnage

Allows machine to “dwell” with required tonnage for a predetermined amount of time.

Coil Line Processing and Material Feed Equipment

We work with providers of process lines and feeding equipment for all levels of production.

STROKE DAMPENERS

When additional punching capacity is required, this feature helps get more punching tonnage without shocking the hydraulic system

DIE CUSHIONSAids in forming processes and for drawing and/or part ejection. |

|

REMOVABLE BED/BOLSTER

Recommended for machines with die cushions to allow access to die cushion for maintenance. Not available with AM/CM models.

RAM CONTROL

As standard the ram travel is controlled via simple mechanical limit switches that control open height, speed change point and the lower limit via a micrometer.

Digital Readout (Non-Programmable)Shows ram location while using the |

|

|

PLC/Programmable Ram ControlControls base functions of press.

|

|

HIGH SPEED HYDRAULIC SYSTEMS:

ADDITIONAL OPEN HEIGHT AND/OR ADDITIONAL STROKE

ADDITIONAL THROAT DEPTH (C-FRAME MODELS ONLY)

Note: Stroke options increases overall height and does not automatically increase open height or closed height. Also, extra open height does not automatically increase stroke. All options quoted may increase dimensions/weight of machine.

OTHER OPTIONS AVAILABLE:

- Safety equipment to user specification

- Special machining

- Special platens

- Air counterbalance

- Special electrics

- Bed/Ram customization

- UL/CSA and other certifications—As standard all components are UL508A compliant

- Special single paint color

- Other options available per customer request

- Scrap chutes and knockouts