DUAL CYLINDER- EV MODEL

STANDARD FEATURES

- Repeatability - (+/-) .0004 Ram repeatability

- CNC Controls - ESA CNC controls w/ 2D integrated CAD and 3D parts viewer

- Back-gauges - High precision servo gauging system with 29" range of motion

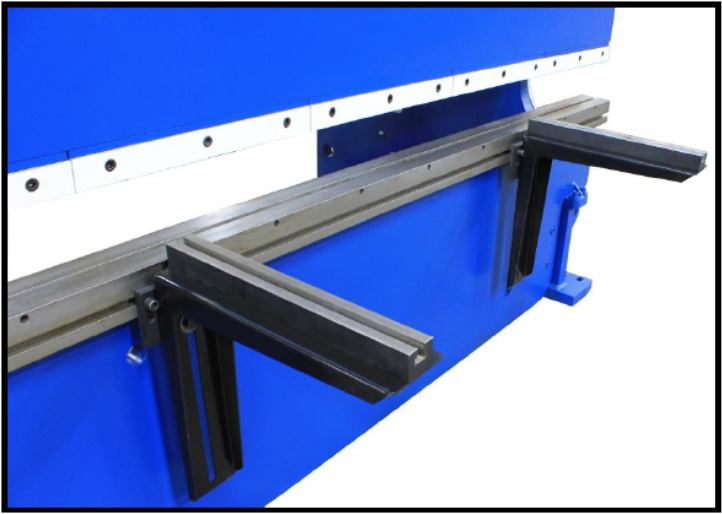

- Work Supports - (2) 24" T-slot support arms with imbedded scales

- Work Lighting - Integrated LED work area lighting

- Tonnage Control - Fully programable CNC tonnage control

- Backup & File Management - USB ports for easy backup and file transfer

- Network Connectivity - RJ45 port for network connectivity

- Off-line Software - Windows based part development software included

- Made in the U.S.A. - built from non-proprietary parts available in the USA. Proudly owned and operated 100% in the U.S.A.

- Warranty - Our unmatched 5 Year Parts/2 Year CNC/5 Year Limited onsite labor comes standard with every machine.

PRECISION

Our model EV press brakes are available from 90 to 1,100 tons up to 24’ with tandem configurations available. Our Y1-Y2, fully proportional hydraulic system provides +,- .0004” of precision ram to bed level accuracy across the length of the machine. All made in in our factory in Clarksdale, MS U.S.A.

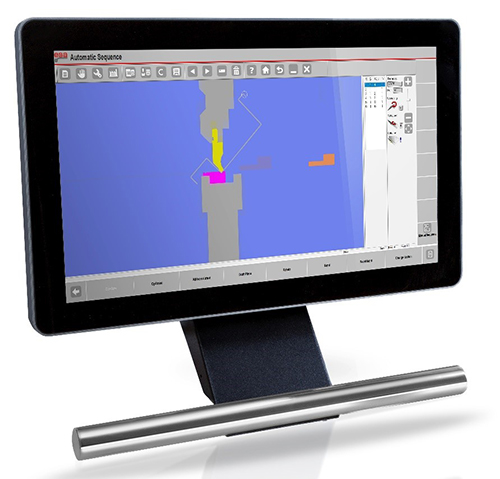

840 2D GRAPHICAL CNC CONTROL

This state of the art control includes remote service/support and diagnostics via the ethernet connection, Windows 10 operating system, a 15” color touchscreen with pendant mount, a full 2 dimensional graphics package, 30,000 hard drive programs, unlimited off-line programmability via USB or ethernet, 2D collision detection and best bending sequences identification plus much more. The 840 controls up to 11 CNC axis plus CNC crowning (optional).

|

|

Like all components on our machinery, this control is non-proprietary and readily available everywhere in the world

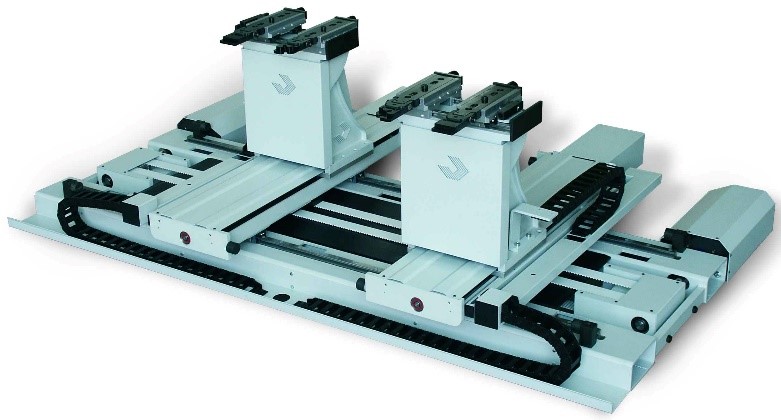

X AXIS SERVO GAUGING SYSTEM

Extremely heavy duty, precision servo gauging system with 29” travel. Available optionally with R, Z1-Z2, X-Prime or Z1-Z2+X1-X2+R1-R2.

|

|

PROGRAMMABLE RAM TILT

The operator has the ability to control and program the tilt of the ram (+,- 3/4” of the centerline) via the CNC for the most precision adjustment required.

PROGRAMMABLE TONNAGE CONTROL

The model EV press brake comes standard with programmable tonnage that allows the operator to choose and save tonnages for each job.

UNLIMITED PARTS AVAILABILITY

All Standard Industrial machines come standard with components that are available everywhere in North America. We use no proprietary components that force you to come back to us for parts. In your manual you will have the original manufacturer’s name and part number of each component so you will never have trouble finding parts.

ONSITE TRAINING

All EV press brakes comes standard with onsite training at customer’s facility (contiguous U.S.). Once the machine is fully installed by your riggers, our experienced technicians arrive at your facility to fully train your operators on operation, preventative maintenance and answer an and all questions about the equipment.

AUTO RETURN OF RAM

Normal operation of ram requires operator to release footswitch to allow ram to return to upper limit. This option makes the ram return automatically even if footswitch is still depressed.

DECOMPRESSION SYSTEM

REQUIRED FOR BOTTOMING APPLICATIONS—allows oil pressure to bleed off to reduce shock to hydraulic system.

LOW SPEED RETRACT

Ram returns in slow press speed for handling of large work pieces.

WARRANTY

5 Year Parts + 5 Year Limited Onsite Labor + 2 Year CNC Warranty. This warranty includes a 5 year limited onsite labor warranty and a 2 year CNC Warranty. Unlimited lifetime telephone support is included at no charge. If during the first 5 years you have an unresolved issue and telephone troubleshooting has been fully exhausted, we will provide onsite labor to take care of the problem. This warranty is based on 3 shifts a day and 24 hour days.

Every machine is also available with our optional 7 Year Extended Warranty that extends the parts warranty by 2 years. NO OTHER MANUFACTURER MATCHES OUR WARRANTY.

SERVICE

We have service capability everywhere in the contiguous United States which can only be expected for a U.S. made machine. We also supply free telephone support for the lifetime of the machine. You talk directly to the people that make your machine.

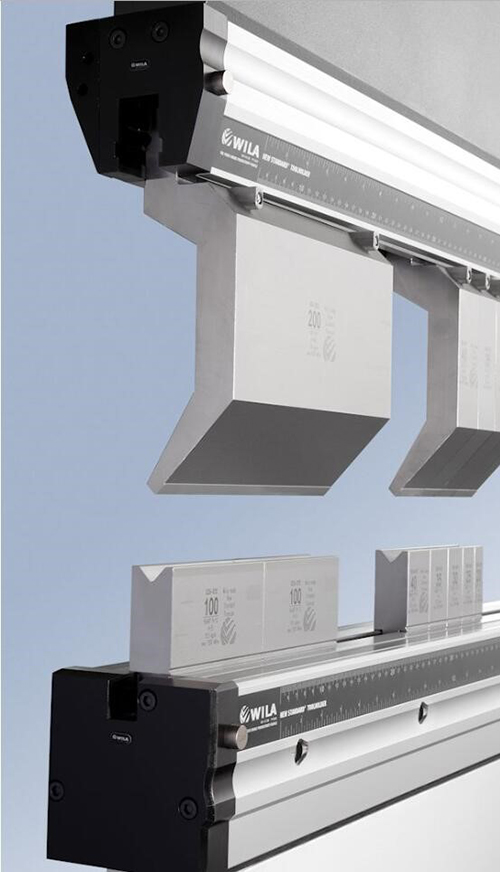

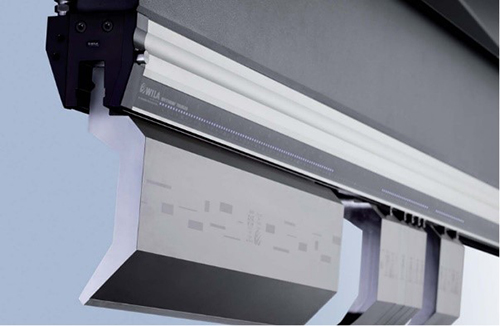

MANUAL RAM CLAMPING

American or New Standard Style Ram Clamping. Extremely heavy duty, spring loaded die clamps for easy, fast die change. Accepts all American style standard and precision ground tooling. All press brakes can be ordered optionally with quick-change, powered ram clamping systems and European clamping systems in lieu of manual system.

EXTREMELY HEAVY DUTY BED CONSTRUCTION

Includes American Style Die Groove as standard. Incredibly heavy-duty lower beams are essential to any well-made press brake to provide the best deflection possible. CNC crowning units are available optionally.

BED FEATURES AND T-SLOT SUPPORT ARMSThe bed of the Y1-Y2 EV press brake includes a groove down the center of the brake bed to accept American style tooling. European beds also available. A t-slot across the front edge of the brake bed is included to allow the (2) standard 24” works supports to slide left to right the length of the bed.

24” T-SLOT SUPPORT ARMSEach machine comes standard with 24” work supports with machined t-slots for precision front gauging. These arms can be adjusted vertically to match tool height and can be adjusted left to right the full length of the bed via the included t-slot across the front edge of the bed.

T-SLOT ACROSS FRONT EDGE OF BEDA 5/8” precision machined t-slot runs the full length of the brake bed. This slot allows the standard 24” support arms to slide left to right the full length of the bed.

RAM CONTROLThe Hand/Foot safety sequence with footswitch is an O.S.H.A. approved 2 hand pedestal control with 3 position footswitch that comes standard on all press brakes. Available optionally are light curtains, Keyence scanning systems and Laser Systems for up close work. As well as interlocking, physical barriers across back of machine if needed. |

|

850W 2D/3D Graphical Control UPGRADE

|

|

RADAN 3D MODELING SOFTWARE

(For more information go to www.radan.com)

State of the art 3D programming software available optionally with the 840 control (download programs only) and 860 control (full download to CNC). This software allows the import of all range of drawing formats and automatic unfolding of your parts. It is available for Solidworks, Autocad and many other software suites.

INCLUDES:

- Automatic bend sequencing

- Automated tool selection

- Tool setup optimization

- Automatic finger positioning

- Support for lifting aids and measurement systems

PRECISION SERVO GAUGING SYSTEMS

All model EV precision press brakes come standard with our heavy duty, 29” travel, precision servo gauging system with manual R/manual Z.

The EV press brakes are available optionally with R, Z1-Z2 and X-Prime servo gauging systems. As well as our full 6 axis gauging system that includes Z1-Z2 + X1-X2 + R1-R2. Available in 29” to 39” travel (special lengths available). All covered by our 5 year parts warranty.

2-4 Axis X+ R (2 axis) or X + R + Z1-Z2 (4 axis)X = Fingers in/out R = Finger up/down Z1-Z2 = Fingers Independently Left/right |

|

|

5 Axis X + R + Z1-Z2 + X-PrimeX-Prime = Allows 1 finger +,- 3” of center for tapered bends |

|

|

6 Axis Z1-Z2 + X1-X2 + R1-R26 axis of full articulation Z1-Z2 = Fingers independently left to right X1-X2 = Fingers independently front to back R1-R2 = Fingers independently up and down |

|

LIGHT CURTAIN WITH FOOTSWITCHFloating blank key-switch included, some programmability. Side barriers included to completely protect throat area of machine. 1 year warranty. |

|

|

LASER GUARDING SYSTEMWraps lasers around punch to allow operator closer to pinch-point and still be O.S.H.A. approved. 1 year warranty. |

|

|

COMPLIANCE OPTIONS INCLUDING UL LISTING, CSA, ZED |

|

|

ADDITIONAL FOOTSWITCH AND PEDESTAL CONTROL FOR 2nd OPERATOR |

|

|

SAFETY GUARDING FOR REAR OF PRESS BRAKEComes with swinging gates and interlocking system for shut down while open. Custom guarding systems available. |

|

CNC CROWNINGFor the most precision requirements, CNC crowning allows the operator to program the desired deflection for each job reducing set up time. |

|

|

RAM AND BED CLAMPING SYSTEMSQuick-change, powered clamping systems for upper and lower tooling providing you the quickest set up times possible. Perfect for American or New Standard style of tooling. Lower clamping available with or without crowning. |

|

|

AMERICAN AND NEW STANDARD PRECISION TOOLINGPrecision ground to +,- .0004” and hardened at wear points. Segmented tooling is the answer for quality and fastest set up times. |

|

|

CNC SHEET ASSISTSWhen operator safety and precision part handling are a priority, our CNC sheet assists are the solution. CNC controlled for precision part following and available for any level of production. (800 series controls required) |

|

|

QUICK RELEASE LINEAR WORK SUPPORTSQuick-change, quick-disconnect style support arms with heavy duty, smooth transition roller guides for easy arm movement. Multiple adjustment points on arms for super precision placement. |

|

EXTENDED WARRANTY

This optional warranty extends the standard 5 year parts warranty by 2 years. Includes:

- 7 year parts in lieu of standard 5 year parts warranty

- 2 year PLC and CNC warranty

- 5 year onsite limited labor warranty

EXTRA STROKE/EXTRA OPEN HEIGHT/DEEPER THROATS/HORN EXTENSIONS

All our machines can be tailor made to your exact needs

ADDITIONAL OPTIONS

Tandem integration of press brakes

Robotic interfaces

Automatic lubrication system w/warning light and auto shut-off

Longer T-slot support arms

Conventional tooling

Custom (single) paint color (sample required)

| Weight (US lbs.) |

Forming/Punching | Bed/Ram (Length) |

Between Frames | Open Height | Stroke | |

|---|---|---|---|---|---|---|

| Model EV90 90 Ton Capacity | ||||||

| EV90-6 | 10,000 | 90/45 | 6' | 4'-5" | 15" | 8" |

| EV90-8 | 12,000 | 90/45 | 8' | 6'-5" | 15" | 8" |

| EV90-10 | 16,000 | 90/45 | 10' | 8'-5" | 15" | 8" |

| EV90-12 | 19,000 | 90/45 | 12' | 10'-5" | 15" | 8" |

| EV90-14 | 24,000 | 90/45 | 14' | 12'-5" | 15" | 8" |

| EV90-16 | 29,000 | 90/45 | 16' | 14'-5" | 15" | 8" |

| EV90-20 | 42,000 | 90/45 | 20' | 18'-5" | 15" | 8" |

| Model EV140 140 Ton Capacity | ||||||

| EV140-8 | 17,000 | 140/70 | 8' | 6'-5" | 16" | 8" |

| EV140-10 | 20,000 | 140/70 | 10' | 8'-5" | 16" | 8" |

| EV140-12 | 23,000 | 140/70 | 12' | 10'-5" | 16" | 8" |

| EV140-14 | 26,000 | 140/70 | 14' | 12'-5" | 16" | 8" |

| EV140-16 | 32,000 | 140/70 | 16' | 14'-5" | 16" | 8" |

| EV140-20 | 45,000 | 140/70 | 20' | 18'-5" | 16" | 8" |

| Model EV200 200 Ton Capacity | ||||||

| EV200-8 | 21,000 | 200/100 | 8' | 6'-5" | 20" | 10" |

| EV200-10 | 24,000 | 200/100 | 10' | 8'-5" | 20" | 10" |

| EV200-12 | 28,000 | 200/100 | 12' | 10'-5" | 20" | 10" |

| EV200-14 | 32,000 | 200/100 | 14' | 12'-5" | 20" | 10" |

| EV200-16 | 36,000 | 200/100 | 16' | 14'-5" | 20" | 10" |

| EV200-20 | 52,000 | 200/100 | 20' | 18'-5" | 20" | 10" |

| Model EV250 250 Ton Capacity | ||||||

| EV250-8 | 24,000 | 250/125 | 8' | 6'-5" | 20" | 10" |

| EV250-10 | 26,000 | 250/125 | 10' | 8'-5" | 20" | 10" |

| EV250-12 | 30,000 | 250/125 | 12' | 10'-5" | 20" | 10" |

| EV250-14 | 36,000 | 250/125 | 14' | 12'-5" | 20" | 10" |

| EV250-16 | 42,000 | 250/125 | 16' | 14'-5" | 20" | 10" |

| EV250-20 | 58,000 | 250/125 | 20' | 18'-5" | 20" | 10" |

| Model EV350 350 Ton Capacity | ||||||

| EV350-8 | 30,000 | 350/175 | 8' | 6'-5" | 20" | 10" |

| EV350-10 | 35,000 | 350/175 | 10' | 8'-5" | 20" | 10" |

| EV350-12 | 40,000 | 350/175 | 12' | 10'-5" | 20" | 10" |

| EV350-14 | 46,000 | 350/175 | 14' | 12'-5" | 20" | 10" |

| EV350-16 | 50,000 | 350/175 | 16' | 14'-5" | 20" | 10" |

| EV350-20 | 68,000 | 350/175 | 20' | 18'-5" | 20" | 10" |

| Model EV450 450 Ton Capacity | ||||||

| EV450-10 | 49,000 | 450/225 | 10' | 8'-5" | 20" | 10" |

| EV450-12 | 53,000 | 450/225 | 12' | 10'-5" | 20" | 10" |

| EV450-14 | 58,000 | 450/225 | 14' | 12'-5" | 20" | 10" |

| EV450-16 | 70,000 | 450/225 | 16' | 14'-5" | 20" | 10" |

| EV450-20 | 85,000 | 450/225 | 20' | 18'-5" | 20" | 10" |

| Model EV550 550 Ton Capacity | ||||||

| EV550-10 | 58,000 | 550/275 | 10' | 8'-5" | 20" | 10" |

| EV550-12 | 65,000 | 550/275 | 12' | 10'-5" | 20" | 10" |

| EV550-14 | 70,000 | 550/275 | 14' | 12'-5" | 20" | 10" |

| EV550-16 | 80,000 | 550/275 | 16' | 14'-5" | 20" | 10" |

| EV550-20 | 1,05,000 | 550/275 | 20' | 18'-5" | 20" | 10" |

| *** All Specifications subject to change *** |