About Us

About Standard Industrial Company

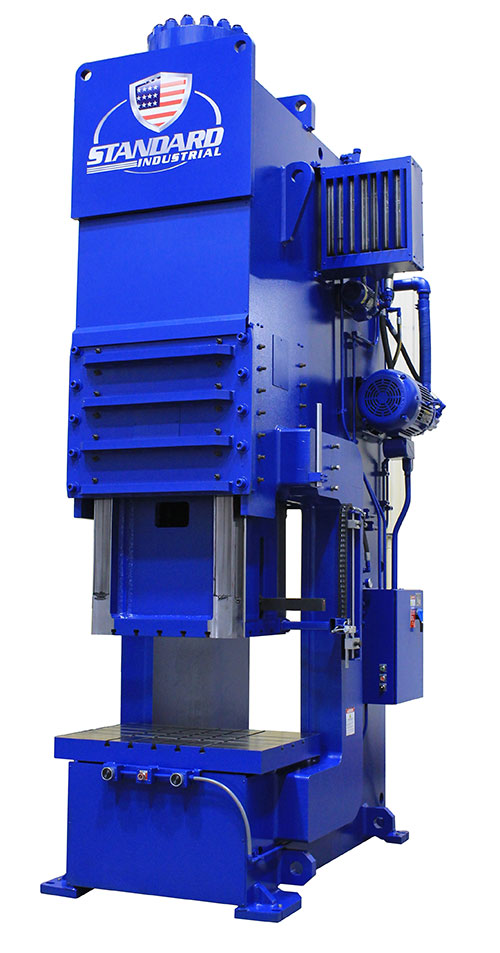

A U.S. Manufacturer of Press Brakes, Shears, & Hydraulic Presses

Unmatched Rigidity and Dependability

5 Year Hydraulic and Electric Parts Warranty + 2 Year PLC/CNC Warranty & 5 Year Limited On-Site Labor Warranty

A Lifetime of Readily Available Components from Your Local Suppliers

Thank you for this opportunity to offer our machinery. Standard Industrial offers a complete line of 100% U. S. made hydraulic Press Brakes, Shears as well as Four Column, C-Frame and Straight Side presses for traditional and non-traditional production facilities. The management/owner team of Standard Industrial has been manufacturing this machinery since 1967 and has thousands of machines in service a...

Government Inquiry Portal

Standard Industrial has earned a reputation as a trusted and reliable supplier of metal fabrication equipment not only in the private sector but also in the realm of government facilities. With their Hub Zone certification and long-standing relationships with U.S. government entities, Standard Industrial demonstrates their commitment to providing top-quality machinery and exceptional service to government facilities worldwide. Hub Zone Certifica